52896WA Advanced Diploma of Civil and Structural Engineering (Materials Testing)

Investigation of the properties of construction materials, the principles which…Read moreGraduate Diploma of Engineering (Safety, Risk and Reliability)

The Graduate Diploma of Engineering (Safety, Risk and Reliability) program…Read moreProfessional Certificate of Competency in Fundamentals of Electric Vehicles

Learn the fundamentals of building an electric vehicle, the components…Read moreProfessional Certificate of Competency in 5G Technology and Services

Learn 5G network applications and uses, network overview and new…Read moreProfessional Certificate of Competency in Clean Fuel Technology - Ultra Low Sulphur Fuels

Learn the fundamentals of Clean Fuel Technology - Ultra Low…Read moreProfessional Certificate of Competency in Battery Energy Storage and Applications

Through a scientific and practical approach, the Battery Energy Storage…Read more52910WA Graduate Certificate in Hydrogen Engineering and Management

Hydrogen has become a significant player in energy production and…Read moreProfessional Certificate of Competency in Hydrogen Powered Vehicles

This course is designed for engineers and professionals who are…Read more

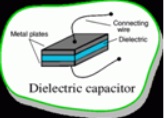

A capacitor is a passive electric element that accumulates energy in the form of electrostatic field. In simple words, capacitor includes 2 conducting plates alienated by the dielectric (an insulating material). The capacitance is inversely relative to the alienation amid the plates and it’s directly relative to the surface area of the conducting plates. Capacitance also relies on the dielectric constant of the material alienating the plates.The customary unit of capacitance is termed as farad, abbreviated. This is a huge unit; other universal units are known as microfarad, abbreviated 1 μF =10-6F (μF) & the picofarad, abbreviated 1 pF = 10-12F (pF).

“An electric circuit element used to store charge temporarily, consisting in general of two metallic plates separated and insulated from each other by a dielectric, also known as condenser.”

“An electric circuit element used to store charge temporarily, consisting in general of two metallic plates separated and insulated from each other by a dielectric, also known as condenser.” A capacitor in general is like a battery. The common factor which is there in a battery & capacitor is that they both store electric energy. Capacitors store electrons inside it for any given time period. A capacitor is a two – ended gear that includes 2 conducting units divided by a non-conducting material. A capacitor actually comprise of 2 conducting surfaces on which energy is stored these surfaces are divided by a lean insulating sheet which has an extremely huge resistance.Some ordinary non-conductive materials that universally exist in a capacitor are Teflon, ceramic, porcelain and cellulose. The dielectric is a material that states the type of capacitor you are using and what is its specific usage. It depends on the kind of dielectric being utilized and the size for the application of high voltage or high frequency appliances.Capacitors are manufactured for a variety of products; some capacitors are so small that they are made for products like calculators, while other super capacitors are manufactured to be incorporated in computer bus. One can see capacitors in all sorts of HVAC systems which includes defrost boards & circuit boards. The most ordinary type of capacitor employed in HVAC system are start capacitor, dual run capacitor & run capacitor. Capacitors in Series:

A capacitor in general is like a battery. The common factor which is there in a battery & capacitor is that they both store electric energy. Capacitors store electrons inside it for any given time period. A capacitor is a two – ended gear that includes 2 conducting units divided by a non-conducting material. A capacitor actually comprise of 2 conducting surfaces on which energy is stored these surfaces are divided by a lean insulating sheet which has an extremely huge resistance.Some ordinary non-conductive materials that universally exist in a capacitor are Teflon, ceramic, porcelain and cellulose. The dielectric is a material that states the type of capacitor you are using and what is its specific usage. It depends on the kind of dielectric being utilized and the size for the application of high voltage or high frequency appliances.Capacitors are manufactured for a variety of products; some capacitors are so small that they are made for products like calculators, while other super capacitors are manufactured to be incorporated in computer bus. One can see capacitors in all sorts of HVAC systems which includes defrost boards & circuit boards. The most ordinary type of capacitor employed in HVAC system are start capacitor, dual run capacitor & run capacitor. Capacitors in Series:

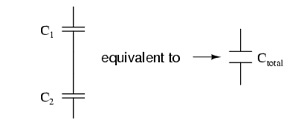

When capacitors are connected in series the total capacitance is even less than any one of the capacitors’ connected in series, individual capacitance. If more than two capacitors are connected in series, the whole outcome is of a solitary (equa

l) capacitor which has the total sum of the plate space of the single capacitor. As we very well know that a rise in the plate spacing, with rest of the factors unaltered, outcomes in fall of capacitance.

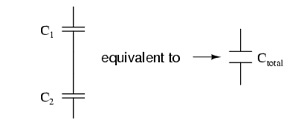

When capacitors are united in parallel the overall capacitance is the total of the solitary capacitor’s capacitance. If more than 2 capacitors are linked in parallel, the whole outcome is that of a solo correspondent capacitor which has the sum total of the

plate surface of the solo capacitor. As we have experienced that an increase in the plate surface, while other essential factors remain same, the outcome is an increase in the capacitance.

Capacitors can be employed in a number of different manners in a variety of electronic circuits. Even though their method of functioning remains precisely similar they can be employed to supply a range of different circuit operations such as-

Coupling capacitor, Smoothing capacitor, Decoupling capacitor. There are many other types of capacitors too that can be employed, maximum of them are discussed below:

1. Ceramic Capacitor: Ceramic capacitor is found in many appliances ranging from radio to RF. By far ceramic capacitors are the most commonly used capacitors; this is because

these capacitors are cheap, reliable & their loss factor is much lower. These ceramic capacitors are used in both leaded and surface mount formats.

- Leaded disc ceramic capacitors for throughout hole mounting which are resin layered.

- Multi-layer surface mount chip ceramic capacitors.

- Specialist microwave bare lead-less disc ceramic capacitors that are intended to be seated in a slit in the PCB and are welded in place.

2. Electrolytic Capacitor:

This type of capacitor is polarized. These capacitors are capable of offering higher capacitance value -generally above 1μF, this type of capacitor is commonly used in low frequency applications.

- ESR Equivalent series resistance.

- Frequency response – This capacitor has limited frequency response.

- Leakage – Even though it has superior

- Level of capacitance for a given volume, they also have a high intensity of leakage.

- Ripple current – While making use of this capacitor in high current applications, it is essential to consider the ripple current, it is suppose to take place.

- Tolerance –This capacitor has have a very wide tolerance

3. Tantalum Capacitor:

These capacitors are even polarized and they too supply extremely high capacitance value for their volume. This kind of capacitor is extremely bigoted of being reversely biased, frequently causing explosion when applied under pressure.

- These capacitors have advanced volumetric efficiency

- These capacitors can be easily fixed in any sort of circuit boards.

- Tantalum capacitors have better frequency attributes

- Tantalum capacitors are extremely dependable, as they do not lose capacitance

Tantalum capacitors can be located in laptop, PCs, airbag circuitry in trucks & cars, mobile phones, pagers and a broad range of other devices. 4. Variable Capacitor:

A variable capacitor is a kind of condenser which helps in accumulating energy by generating electric fields. The forte of this gadget is that the capability to preserve power can be altered

either repetitively or deliberately through mechanical or electronic methods. Variable capacitor’s capacitance may be altered all through the lifetime of the gadget itself . A mechanical structure is employed in the capacitor, which permit altering the remoteness amid the different sets of plates, or specifically, the surface of the overlying plate area, together with the variable capacitance diodes. All these alter their capaci

tance behavior owing to the reverse voltage bias application.

- air variable capacitor

- vacuum variable capacitor

- variable tuning capacitor

- high voltage variable ceramic capacitor

5. Paper Capacitor:

Paper capacitors are prepared from paper or oil-impregnated paper and aluminum foil sheets spin into a drum and conserved with wax. These paper capacitors were normally employed but are now substituted by the polymer or plastic made capacitors. The paper capacitors are large, extremely hygroscopic and drenches dampness which roots to loss to the dielectric undignified its total performance is the main disadvantage with this sort of capacitors. The other options consist of paper-polyester, Kraft paper and oil-impregnated capacitor.

This type of capacitor is not in use much these days but this kind of capacitor still supply very superior level of constancy, lower loss & accuracy where space is not a matter of concern.

7. Polystyrene Film Capacitor:These are relatively cheap sort of capacitors but supply a close tolerance capacitor wherever required. These are tubular in shape; this is because the plate or dielectric sandwich is rolled collectively.

8. Polyester Film Capacitor:These capacitors are employed where cost is a concern as they do not supply a superior tolerance. These capacitors are in general only accessible as leaded electric constituents.

9. Polycarbonate Capacitor:This type of capacitoris applied in appliances where performance & reliability is important. The polycarbonate film in extremely steady and allows superior tolerance capacitor to be manufactured which will uphold capacitors capacitance value over time.

10. Metalized Polyester Film Capacitor:

This is basically a polyester film capacitor the only difference amid the two is that in metalized polyester capacitor, polyester film is metalized. The metalized polyester film capacitors are usually only acces

sible as leaded electric constituents.

11. Polypropylene Capacitor:

This capacitor is employed when a superior tolerance is required than polyester capacitors supply. This capacitor makes use of polypropylene film for the dielectric. These capacitors are usually only accessible as leaded electric constituents.

12. Glass Capacitors:

This capacitor makes use of glass for the dielectric. This is an expensive capacitor but offer extremely superior level of performance in means of very low loss, higher RF curre

nt ability, no piezo-electric noise and some other salient attributes that make them perfect for several performance RF applications.

13. Super Capacitors:

Super capacitors come from a family of electrochemical capacitors. These capacitors are sometimes named as electric double layer capacitor (EDLC) or ultracapacitor. They do not comprise of any traditional solid dielectric. The capacitance value of a super capacitor is determined on the basis of 2 storage principles; these 2 principles contribute to capacitor’s overall capacitance.

Super capacitors are low in weight & cheap as well that’s why it’s the most popular capacitor in market these days. They are employed in most portable electronics & phones, together with aircrafts & automobiles. The new technology super capacitors are flexible and biodegradable. Advantages of a Super Capacitor:

- No danger of overcharge

- Very high rates of charge and discharge

- High cycle efficiency (95% or more)

- Virtually unlimited life cycle–cycles millions of time-10 to 12 year life

- Charges in seconds

- Low impedance

- Super capacitors and ultra capacitors are relatively expensive in terms of cost per watt

12. Ultra capacitor:

Ultracapacitors & super capacitors are one and the same, it has been explained above please refer.

Capacitor Capacitance Calculator:

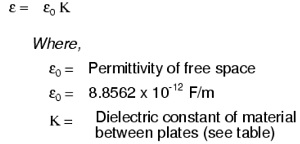

This capacitance calculator evaluates the capacitance amid two parallel plates. The 1st calculator is metric, while the 2nd is inches. Small valued capacitors can be engraved into a PCB for RF purposes, but underneath ma

jority conditions it is extra cost effectual to make use of separate capacitors.A variety of dielectric constants are given below.

Equation:

C= K*EO*A/D, where Eo= 8.854×10-12

Where:

K-Is the dielectric constant of the material,

A-Is the overlying surface area of the plates,

d-Is the distance amid the plates, and

C-Is capacitance

Capacitor Bank:

A Capacitor Bank is a cluster of a number of capacitors of the similar rating that are coupled in series or parallel with one another to accumulate electrical energy. The resultant bank is then employed to work against or correct a power factor

pause or phase alteration in an AC (alternative current) power supply. They can also be employed in a DC (direct current) power supply to boost the ripple current capability of the power supply or to boost the total sum of energy accumulated.

Capacitor banks operate on the similar theory that a solitary capacitor do; they are intended to accumulate electrical energy, just at a bigger capability than a solitary appliance.

Applications of Capacitors:

Capacitors are used for a number of purposes, it’s the most commonly found device in any sort of electronic gadget. Each kind of capacitor has its individual advantage & disadvantage and as a result, the applications of the ca

pacitor can be dissimilar. A number of capacitors are good for elevated frequency utilization, while others can be employed for low frequency purposes. Without a doubt it is essential to have the correct capacitor for the precise usage of the circuit is to

function appropriately.

- Timing–for illustration with a 555timerIC to control the charging & discharge.

- Coupling–for illustration amid junctures of an audiosystem and to unite a loudspeaker.

- Storing energy–for illustration in a camera’s flash circuit.

- Smoothing – for illustration in a power supply.

- Tuning–for illustration in a radiosystem.

- Filtering–for illustration in the tone controller of an audiosystem.

Source: https://www.electronicshub.org/different-types-of-capacitors/

Professional Certificate of Competency in Advanced TCP/IP-Based Industrial Networking

Designed for engineers and technicians who need practical knowledge in…Read moreProfessional Certificate of Competency in Allen Bradley Controllogix / Logix5000 PLC Platforms

Designed for engineers and technicians who need practical knowledge in…Read moreProfessional Certificate of Competency in Arc Flash Protection

Designed for engineers and technicians who work in the electrical…Read moreProfessional Certificate of Competency in Chemical Engineering and Plant Design

Designed for engineers and technicians who need practical knowledge in…Read moreProfessional Certificate of Competency in Circuit Breakers, Switchgear and Power Transformers

Designed for engineers and technicians who need practical knowledge regarding…Read moreProfessional Certificate of Competency in Control Valve Sizing, Selection and Maintenance

Designed for engineers and technicians who need a solid understanding…Read moreProfessional Certificate of Competency in Electrical Power System Fundamentals for Non-Electrical Engineers

Designed for engineers and technicians who need to understand the…Read moreProfessional Certificate of Competency in Electrical Power System Protection

Designed for engineers and technicians who need practical skills and…Read moreProfessional Certificate of Competency in Electrical Wiring Standards: AS/NZS 3000:2018 (Australia and New Zealand Only)

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Fundamental E & I Engineering for Oil and Gas Facilities

Designed for engineers and technicians who need to update their…Read moreProfessional Certificate of Competency in Gas Turbine Engineering

Designed for engineers and technicians who need practical skills in…Read moreProfessional Certificate of Competency in Hazardous Areas and Intrinsic Safety For Engineers and Technicians

Designed for engineers and technicians who need to understand the…Read moreProfessional Certificate of Competency in Heating, Ventilation and Air Conditioning (HVAC)

Designed for engineers and technicians from a wide range of…Read moreProfessional Certificate of Competency in IEC 61850 Based Substation Automation

Designed for engineers and technicians who need to understand the…Read moreProfessional Certificate of Competency in Industrial Data Communications

Designed for engineers and technicians who need to understand how…Read moreProfessional Certificate of Competency in Instrumentation, Automation and Process Control

Designed for engineers and technicians who need to gain practical…Read moreProfessional Certificate of Competency in Machine Learning and Artificial Intelligence

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Mechanical Engineering

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Onshore and Offshore Pipeline Systems

Designed for engineers and technicians who need to gain an…Read moreProfessional Certificate of Competency in Power Distribution

designed for engineers and technicians who need to gain a…Read moreProfessional Certificate of Competency in Practical Machine Learning Using Python for Engineers and Technicians

Designed to use Python Programming to work with machine learning…Read moreProfessional Certificate of Competency in Practical Python for Engineers and Technicians

Designed for engineers and technicians who need to understand the…Read moreProfessional Certificate of Competency in Programmable Logic Controllers (PLCs) & SCADA Systems

Designed for engineers and technicians who need to get practical…Read moreProfessional Certificate of Competency in Project Management for Engineers & Technicians

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Safety Instrumentation Systems for Process Industries

Professional development course designed for engineers and technicians who want…Read moreProfessional Certificate of Competency in Sewage and Effluent Treatment Technologies

Designed for engineers and technicians who need practical skills and…Read moreProfessional Certificate of Competency in Structural Design for Non-Structural Engineers

Professional development course designed for engineers and technicians who need…Read moreProfessional Certificate of Competency in Substation Design (Main Equipment)

Professional development course is designed for engineers and technicians who…Read moreProfessional Certificate of Competency in Substation Design (Control, Protection and Facility Planning)

Designed for engineers and technicians who need to gain practical…Read moreProfessional Certificate of Competency in the Fundamentals of Process Plant Layout & Piping Design

Professional development course is designed for engineers and technicians who…Read moreProfessional Certificate of Competency in Practical Mechanical Sealing

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Fundamentals of Road Construction

This professional development course is designed for engineers and technicians…Read moreProfessional Certificate of Competency in Specification and Technical Writing

Designed for engineers and technicians who need to understand how…Read moreProfessional Certificate of Competency in Hydraulics and Pneumatics

Overview of all aspects related to the construction, design, operation,…Read moreProfessional Certificate of Competency in Big Data and Analytics in Electricity Grids

This course explores the use of big data & data…Read moreProfessional Certificate of Competency in Renewable Energy Systems

This course covers various renewable energy systems that are popular…Read moreProfessional Certificate of Competency in Smart Grids

A smart grid is an electricity network that uses digital…Read moreProfessional Certificate of Competency in Hydrogen Energy – Production, Delivery, Storage, and Use

Hydrogen energy short course designed for engineers and professionals interested…Read moreProfessional Certificate of Competency in Earthing and Lightning Protection

Designed for engineers and technicians who need to understand the…Read moreProfessional Certificate of Competency in Building Information Modelling (BIM)

This professional development course is covering practical aspects of using…Read more