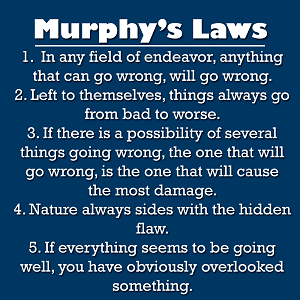

Murphy’s Law is especially quoted in engineering and as most of you would well know says: “If anything can go wrong, it will”. Often, we add: “and at the worst possible time, in the worst possible way”.

Origin of Murphy’s Law

The Law’s (supposed) origin was in engineering where Captain Ed Murphy, an engineer at Edwards Air Force Base, was dealing with a technician who incorrectly wired a strain gauge bridge…

Dear Colleagues

Murphy’s Law is especially quoted in engineering and as most of you would well know says: “If anything can go wrong, it will”. Often, we add: “and at the worst possible time, in the worst possible way”.

Origin of Murphy’s Law

The Law’s (supposed) origin was in engineering where Captain Ed Murphy, an engineer at Edwards Air Force Base, was dealing with a technician who incorrectly wired a strain gauge bridge (wired backwards) for doing gravity tests which as a result gave a (totally wrong) zero reading. There is vigorous debate about whether the engineer gave the incorrect wiring diagram to the technician or whether it was just mistakenly wired up. Whatever happened, the law is now firmly linked with Captain Murphy. And the set-up should have been meticulously tested before being put into service (which it wasn’t).

Uncertainty Principle

I reckon this is a reflection of a fundamental principle of engineering about the lack of precision which results in measurement uncertainty. We can never know precisely the value of anything to any arbitrary level of precision. At the sub-atomic level, Heisenberg’s principle makes this point, that for example that the more precisely you try and measure the location of a particle, the less precisely you will measure its momentum (and vice versa for trying to measure momentum precisely). This doesn’t reflect on your ability to measure, but on the nature of the system itself.

Risk Analyses

In Safety engineering, we do what is called a risk analysis where we identify what types of harm could arise from what we are planning to make or do. We can then establish the probability of the occurrence and then multiply this by the severity of the harm (broken finger, to amputated arm) and we end up with the Risk. If the Risk is great enough, we can then apply a $ value to it and determine how much time and money to spend in reducing it to a tolerable risk. It is impossible to make anything totally unequivocally safe. So as far as Murphy’s Law and risk management is concerned, if you have conducted your risk assessment correctly, then you must expect that the consequences it predicts will eventually come to pass.

And remember: “Absence of proof is not proof of absence”. For example, many years ago with the ill- fated space shuttle launch, a proper risk analysis would presumably have shown that the foam chunks falling off its booster and damaging its thermal tiles would have correctly predicted the deaths and destruction of the craft during re-entry due to the defective tiles. However, NASA believed that because they had not seen such problems so far, they would continue not to see them.

So please continue to embed awareness of Murphy’s Law into your daily engineering life and constantly seek to minimise the consequences of risk.

With our constant litany of woe with IT stuff, I think we are all familiar with Murphy’s Computer Laws (Finagles Rules) – well, I certainly am:

What Every Computer Consultant Needs to Know:

- In case of doubt, make it sound convincing.

- Do not believe in miracles. Rely on them.

Thanks to Keith Armstrong for his illuminating article

Yours in engineering learning

Steve

Mackay’s Musings – 27th Sept’16 #619

780, 293 readers – www.eit.edu.au/cms/news/blog-steve-mackay