This Plastic Free July serves as a reminder that engineers use different polymers than those that pollute the oceans – but have a role to play in environmental management.

The Australian civil action movement Plastic Free July started in 2011. Initially, the campaign included the movement’s founder and a small group from the local government in Western Australia.

Now it aims to share Plastic Free solutions to help reduce plastic waste globally.

According to the group, millions of people can make a huge impact by making small changes that don’t include as much plastic. The collective effort has mass environmental effects and also offers a lesson in personal choices.

Plastic Free July challenge aims to start solution-driven action formulated around key aspects.

1. Improve recycling: Follow local recycling guides and put items in the right bin. Petition governments to require businesses to use recycled plastic in their products and packaging.

2. Embrace a circular economy: Encourage businesses and organizations to move away from the concept of single-use plastic and rather move towards a circular economy that promotes recycling and the reuse of materials.

3. Extended producer responsibility (EPR): Have businesses own their product management lifecycle. This involves producers considering the end-of-life of the products they sell, and making it easy for customers to dispose of products thoughtfully. It’s estimated that this could increase recycling by up to 40%.

Focused on the individual however Plastic Free July aims that people make more informed choices, like opting not to use plastic on takeaway coffee cups, not packing sandwiches in plastic, or not buying anything that is packaged in single-use plastic for a month.

When it comes to engineering the relationship to plastic is a bit more complex, since plastic is vital for engineering practices and applications.

The good news is that central to engineering plastics is the fact that it is completely different from plastics used in packaging or products, and as a result, are a lower threat to the environment.

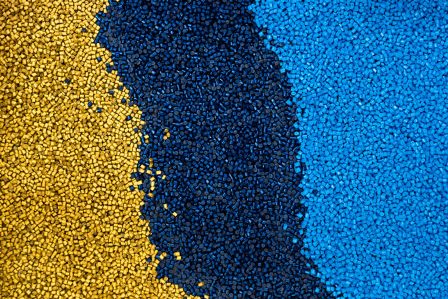

Commonly thermoplastics used for engineering include:

• ABS (Acrylonitrile-Butadiene-Styrene)

• LCP (Liquid Crystal Polymers)

• PBT (Polybutylene Terephthalate)

• PEEK (Polyaryletheretherketone)

• PMMA (Polymethyl methacrylate)

• PA (Polyamide)

• PSU/P/PPSU (Polyarylsulfone)

• PC (Polycarbonate)

• PI (Polyimide)

•PVDF (Polyvinylidene fluoride)

•TPE-E (Thermoplastic polyester elastomer)

•UHMWPE (Ultra-high-molecular-weight polyethylene)

The plastics are considered highly recyclable and are often recycled when disposed of correctly.

Plastic lifecycle and the engineering influence

Engineering has a head start in this aspect as most if not all machines and technology are often stripped for parts before disposing of them.

It means that in practice engineering plastics don’t simply land in the ocean or in landfills – they are often handled first.

This also means that these plastics often get recycled. Up to 100% of engineering plastics are recyclable and most often those plastics are recycled.

When they are not, measures are in place for the correct disposal of these plastics. But it doesn’t mean engineers are excluded from plastic-free movements.

Engineers can play a big role in ensuring the plastic circular economy is correctly deployed globally.

With systems and processes, engineers can start by calculating all aspects of production.

That includes knowing how much CO2 is released into the atmosphere as a result of manufacturing, if there are better solutions for a product that doesn’t rely heavily on plastic, they can consider energy use, effective water management and also sit behind tools that calculate sustainability, systems that consider the environmental impact of materials and also estimate the life-cycle of products.

What engineers know about plastic

The paper Engineering Plastics: Market Analysis and Recycling Methods make the distinction that engineering plastics are usually used for high-performance applications and have qualities like heat resistance, chemical resistance, flame retardance, or mechanical strength. This means these plastics are more effective and not produced in high-volume like commodity plastics.

Commodity plastics have weak mechanical qualities and are almost always made from Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), or Polyvinyl chloride (PVC).

The paper mentions that thermoplastics used by engineers have low or no decline in inefficiency when recycled and in Europe, it is estimated that 99% of these plastics are recycled.

Sort it out

However, the paper says that it is of high importance that these plastics are correctly identified for recycling.

The identification of these plastics is often considered difficult because it falls in the class of Waste Electrical & Electronic Equipments (WEEE). For recycling to be done successfully the following needs to be considered:

• There is a wide selection of essential polymers for use.

• There is a broad variety of additives that can be used to alter basic polymer properties.

• There is a broad range of polymer blends or compounds that can be developed to achieve the required properties.

To make the correct identification of engineering plastics, we need to consider their melting behavior, the color of flame/ kind of smoke they produce, and finally the odor of the material.

The recycled plastics from WEEE can, however, be used for the high-end application, or blending it with other plastics.

The conclusion remains that it is relatively more difficult to obtain scrap materials for engineering plastics compared to commodity plastics because many parts of the plastic lifecycle are already in place.

Engineers can however consider their relationship with commodity plastics more effectively, as suggested by Plastic Free July.

References:

Engineering Plastics: Market Analysis and Recycling Methods. Available from: https://www.researchgate.net/publication/349009934_Engineering_Plastics_Market_Analysis_and_Recycling_Methods.